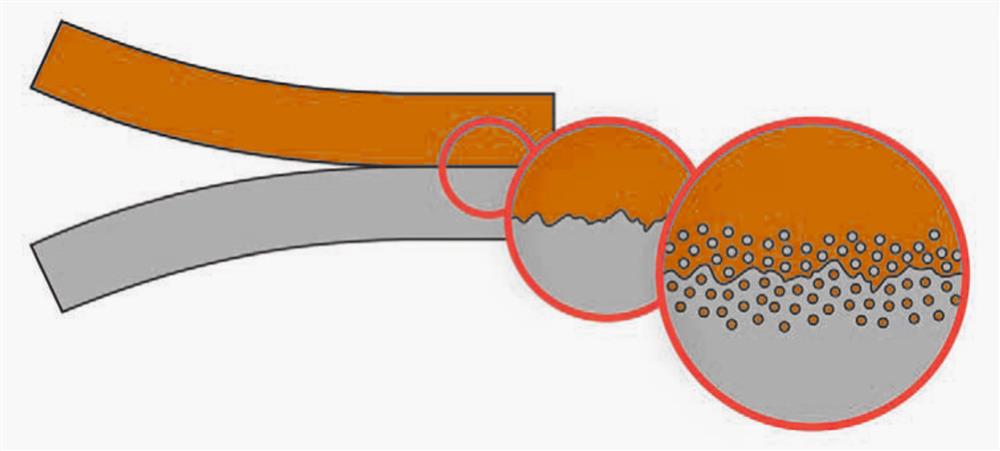

Pure copper that has gone through the processing procedure then needs to be smelted in order to form it into coils sheets and other forms. Copper is refined and cast.

Copper Cookware How Its Made Falk Culinair Usa

Copper Cookware How Its Made Falk Culinair Usa

The malleability of the material made it relatively simple to shape implements by beating the metal.

How its made copper. About press copyright contact us creators advertise developers terms privacy policy safety how youtube works test new features press copyright contact us creators. From it they fashioned crude hammers and knives and later other utensils. The refining techniques employed by copper producers depend on the ore type as well as other economic and environmental factors.

The copper is exposed to high heat that is found in flash furnaces that are oxygen enriched for extremely high temperatures. We see this stuff every day. This native copper is the material that humans employed as a substitute for stone.

Copper is found in the free metallic state in nature. We never think how many steps it takes to get it. Currently about 80 of global copper production is extracted from sulfide sources.

The molten copper which is about 99 5 pure is then poured into molds to form large electrical anodes which act as the positive terminals for the electrorefining process. Copper products need to be smelted. 9 each copper anode is placed in an individual tank or cell made of polymer concrete.

Copper is typically extracted from oxide and sulfide ores that contain between 0 5 and 2 0 copper.