Heat the milk to between 72 c to 74 c for 15 to 20 seconds. Ultra high temperature uht pasteurization.

The spinning causes the milk to separate from debris and floating bits of bacteria.

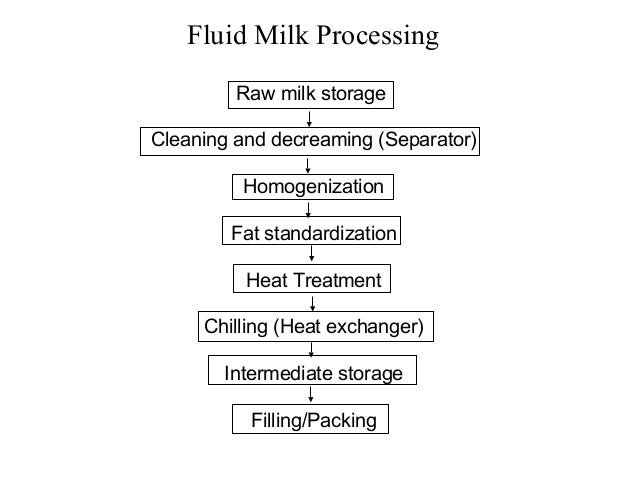

Stages of milk processing. Pasteurization is a heat treatment process that. Most of the milk in developing countries is processed by small scale processors who produce a variety of milk products. The usable life of milk can be extended for several days through techniques such as cooling which is the factor most likely to influence the quality of raw milk or fermentation.

The milk produced during buffaloes lactation period differs due to region and availability of feed. Whole milk once approved for use is pumped into storage silos where it undergoes pasteurization homogenization separation and further processing. The extreme heat targets coxiella burnetii which causes q fever.

Milk processing allows the preservation of milk for days weeks or months and helps to reduce food borne illness. The type of processing employed may vary from country to country and region to region depending on local tastes dietary habits culinary traditions and market demand. Milk is picked up by a handler who takes a sample and then pumps the milk from farm s bulk tank into the milk truck.

Milk is obtained from the cow or goat sheep or water buffalo under sanitary conditions and cooled to 45 f 7 c within 2 hours of milking. However its thermal stability is lower so mixed milk a mixture of buffalo and cow milk is preferable for ultra high temperature uht treatment. After clarification is completed the milk is spun once again to separate heavier and lighter milks.

Clarification is a step in milk processing that ensures the milk will be free of bacteria and debris. Milk is put into large vats that continually spin. Lactation secretion and yield.

Targets resistant pathogenic bacteria spores clostridium botulinum spores. The milk is sent through stainless steel pipes to large refrigerated vats then stored at 5 c or less. Heat the milk to between 135 c to 140 c for 2 to 4 seconds.

Within 48 hours milk is taken in tankers to a milk factory where it s pasteurised and homogenised. Milk from buffaloes can be processed like milk from cows. Every particle of milk is heated to a specific temperature for a specified period of time and cooling it again without allowing recontamination.