What methods of making steel changed the steel industry. In the traditional form of steel making steel comes from a material known as pig iron.

Limiting dissolved gases such as nitrogen and oxygen and entrained impurities in the steel is also important to ensure the quality of the products cast from the liquid steel.

Improved the process of making steel. It was named after the british inventor sir henry bessemer who worked to develop the process in the 1850s. Steelmaking is the process of producing steel from iron ore and or scrap. Other processes which are developing are the fuel oxygen scrap fos process and spray steelmaking which consists in pouring iron through a ring the periphery of which is provided with jets through which oxygen and fluxes are blown in such a way as to atomise the iron the large surface to mass ratio provided in this way giving extremely rapid chemical refining and conversion to steel.

We have gathered all our steel manufacturing information and created a. The bessemer steel process was a method of producing high quality steel by shooting air into molten steel to burn off carbon and other impurities. The bessemer process and the open heart process.

Traditional methods of steel making. Bessemer process improved the process of making steel. This person s name is synonymous with electricity because of his development of and inventions for its use.

In steelmaking impurities such as nitrogen silicon phosphorus sulfur and excess carbon are removed from the sourced iron and alloying elements such as manganese nickel chromium carbon and vanadium are added to produce different grades of steel. Inventor who developed the idea of a central electric power station weegy. Whether you re producing steel from iron ore or scrap and your end product is several inch thick slabs or galvanized sheet less than a millimeter thick you are always looking for technologies that improve each stage of the steel manufacturing production process from incoming raw materials to the final coating line.

Improved the process of making steel weegy. Steel making is an selective oxidation process by which the impurities are removed. Thomas edison is the inventor who developed the idea of a central electric power station.

The modern day process for how steel is made is far more effective than methods used in the past and technological developments have further improved upon the steel manufacturing process.

Zippo windproof lighters including slim lighters use lighter fluid as fuel. For all practical purposes charcoal lighter fluid does not evaporate at room temperature and is termed combustible.

Zippo Premium Lighter Fluid By Timpson

Zippo Premium Lighter Fluid By Timpson

I m going to take them overseas and want to make sure they don t already come with fuel so i can put them in my checked luggage.

Do zippo lighters come with fuel. If a zippo breaks down no matter how old the company will replace or repair the lighter for free. Additionally zippo lighters are known for the lifetime guaranty they carry. Your lighter is backed by the world famous zippo guarantee it works or we fix it free.

If you have any questions about the performance of your lighter or to obtain service visit our repairs page or call zippo consumer relations at 814 368 2700. In one instance a zippo lighter transported in a shirt pocket blocked a bullet. What type of fuel do zippo lighters use.

Do new zippo lighters come with fuel inside them. No it does not come with fuel you have to buy the special zippo fuel seperately also zippos do not work with any other fuel than special zippo fuel and then you have to take the part out of the. However alternative fuels aren t recommended in zippos because they might clog the zippo.

When someone pushes down on the striker with her thumb the wheel turns rapidly over the flint creating hot sparks. In a pinch you can also use other fuels in a zippo lighter including butane naptha also called white gas or coleman fuel or gasoline. Technically it is flammable.

200 000 zippo lighters were owned by u s. Military personnel in the vietnam war. I ve heard of people using 99 isopropyl alcohol methylated spirits or bacardi 151.

Zippo lighter fuel is highly volatile. Zippo lighters differ from standard varieties in that the wire covered non flammable wick is always kept saturated in flammable fluid. Zippo blu lighters use butane gas for fuel.

At room temperature vapors are always present that can be ignited with a flame or even a spark.

Sponge flies also known as spongilla flies neuroptera sisyridae are specialist predators of freshwater sponges. Today the sponges you buy at the store are likely made from synthetic materials and produced in a factory.

Humans have a lot in common with the humble sea sponge according to research that changes the way we think about animal evolution.

How are sponges used by humans. They use their elongated mouthparts to pierce the sponge and suck the fluids within. The larvae hatch and drop into the water where they seek out sponges to feed on. A research team report that a collaborative study found sponges.

The female lays her eggs on vegetation overhanging water. A human made sponge is called a sponge because humans used to use sea sponges. But natural sponges are animals that come from the sea and have been used for a long.

But you can spend a lot less for them if you make your own. As a golf club manufacturer i have had the privilege of visiting many of the top club making facilities in china.

Diy Toddler Golf Clubs And Putting Green I Can Teach My Child Toddler Golf Clubs Diy Toddler Kids Golf

Diy Toddler Golf Clubs And Putting Green I Can Teach My Child Toddler Golf Clubs Diy Toddler Kids Golf

The key thing is to build up the width of the shaft with duct tape.

How to make a golf club. Cut a piece grip tape a little smaller than the size of the grip and wrap it around the butt end of the shaft. Golf club hobbyists say it makes them better at golf whatever better means. Made some short clubs for bryan jordan and isaac.

For weatherspoon a big hitting competitive amateur in his day it s more than the number. As happy as i was to make them i had a problem in that golf club covers were a project that i had never considered knitting before so i didn t have a favorite go to pattern. Rotate them slightly to make sure that they are completely covered by the epoxy.

Molten wax is poured into the die cavity and allowed to harden. The manufacturing method of a golf club depends on the type of club being manufactured. Make sure the shaft is completely.

Make sure there is a little bit hanging over the end and tuck it into the shaft. Recently a friend asked me to make several sets of golf club covers for some of his fellow golfers. Club head is made from metal.

Using the rubber shaft holder set the assembled club into your vise. Knitted golf club cover pattern. If you are not very handy making golf clubs may seem impossible but with the right.

Besides you will have a set that is right for your game which will translate into lower scores. The die consists of two halves with a hollow cavity that is the exact shape and size of the desired club head. See more ideas about golf clubs golf golf club art.

Use your hand to mix the water and detergent until the water begins to bubble. If you don t have a bucket fill a deep sink or a bath with water and detergent instead. Put the shaft inside the hosel after you liberally apply epoxy to both pieces.

They turned out great. Mix warm water and 2 us tbsp 30 ml of detergent in a bucket. Fill a bucket with warm water and then measure in the dishwashing detergent.

The shaft is connected to the golf club head with screw threads. When you set out to buy a new set of golf clubs you will soon realize that you can spend 1 000 or more for top of the line models. Nov 3 2013 explore cath lunghusen s board golf clubs repurposed on pinterest.

Make a smooth wrap with the tape or you might have trouble putting the grip on. Irons fairway woods wedges hybrids and putters are generally cast while drivers and high end iron sets are manufactured using a forging process.

An article entitled how cat litter is made appeared in cat fancy magazine october 1994. The downside of using sand as kitty litter is that it is easily tracked all over the house in your cat s paws.

10 Best Clumping Cat Litter In 2020 Catthink

10 Best Clumping Cat Litter In 2020 Catthink

If you ve got newspaper or scrap paper baking soda and dish soap then you can make your own homemade clumping cat litter.

How to make clumping cat litter. Grab a handful of the wet shreddings and squish with your hands under running water. When clumping litter is used the cat owner can remove the clumps then add more litter to the box eliminating the need to refill it with every cleaning. Soak the paper in warm water mixed with a few squirt of gentle biodegradable dish soap.

The shredded paper will take on a cooked oatmeal consistency. Carefully tilt the scoop down so some fresh pellets can roll off and fall back into the litter box. You ll need to soak the shredded paper in a mixture of warm water and dish soap.

Empty the contents on the litter scoop into a container you use for cat litter. In an article on groundswell katherine manchester says conventional clay clumping litter is an offender for a whole host of reasons. Shockingly the article contains no cautions against the use of clumping litters even though the description of one of the main ingredients in such products should be enough to alarm any thinking person.

According to wikipedia non clumping cat litters are usually made of zeolite diatomite and sepiolite. Dig in the litter with the scoop to find any urine soaked pellets on the bottom. Put the rinsed and squeeze dried newspaper in a dry tub separate clumps and knead baking soda into the paper until you end up with a crumbly mixture.

Remove pellets that are darker in color and have fully expanded in size. The major drawback of clumping litter appears to be its tendency to track that is for the finer granules to stick to the cat s paws when it leaves the box. Soak the shredded newspaper in water to allow some of the ink to wash off then rinse.

The paper won t become completely clean but the water will turn grey. Clumping litter allows cat waste to be easily removed from the box so you will be more likely to clean it often which will make your cat very happy. Your house will smell better too.

Though clumping litter is a natural product it is harvested by strip mining a decidedly unfriendly process. After 30 minutes drain the paper and rinse in fresh water. Make homemade clumping cat litter from dish soap and baking soda.

Over two million tons of clay are mined in the united states every year just to be turned into cat litter. Drain then sprinkle all over with baking power. Automatic litter boxes are even more convenient and they use clumping litter almost exclusively.

How to diy. A litter box mat can help cut down on the tracking.

As an ingredient of air oxygen is usually the easiest to find. A fire naturally occurs when the elements are present and combined in the right mixture.

Fire Extinction Methods And Approaches Elite Fire

Fire Extinction Methods And Approaches Elite Fire

The 3 things a fire needs are heat fuel and oxygen.

What 3 ingredients are required to ignite a fire. Hardwood is harder to light when starting a fire but lasts for a very long time and burns with more heat. On planets such as venus and mars with atmospheres containing far less oxygen fires would be hard to start. Heat fuel and oxygen.

Fire also is a glowing reminder of the oxygen that pervades our world. What three ingredients are required to ignite a fire. If just one of these components is removed the fire triangle will collapse and the fire will be extinguished.

The triangle illustrates the three elements a fire needs to ignite. Any flame requires three ingredients. Lacking even one a fire won t burn.

The fire triangle or combustion triangle is a simple model for understanding the necessary ingredients for most fires. The sides of the triangle represent the interdependent ingredients needed for fire. The three elements that are needed to start a fire are oxygen heat and fuel.

The three things that are required to start a fire are fuel oxygen and heat which form the fire triangle. The three ingredients of a fire triangle are. 3 things a fire needs.

Heat fuel and an oxidizing agent usually oxygen. Those three elements are part of the fire triangle which illustrates the int history. The fire triangle is a simple way of understanding the elements of fire.

Oxygen fuel and heat. These three elements work together to help a fire start and take over. Torch lighter fluid and newspaper.

A fire can be prevented or extinguished by removing any one of the. All three are dependent on one another which means that a fire cannot be started if even one of them is missing. However if any of the three elements are removed from a fire then it will extinguish and no longer pose a threat.

The fire triangle or combustion triangle is the three components needed to ignite and sustain a fire. Heat fuel and oxygen. Add oxygen to fan your flames.

Oxygen ignition and fuel. A solution to keeping your fire burning is to start the fire with softwood and switch to hardwood when you have a good stable flame with some embers.

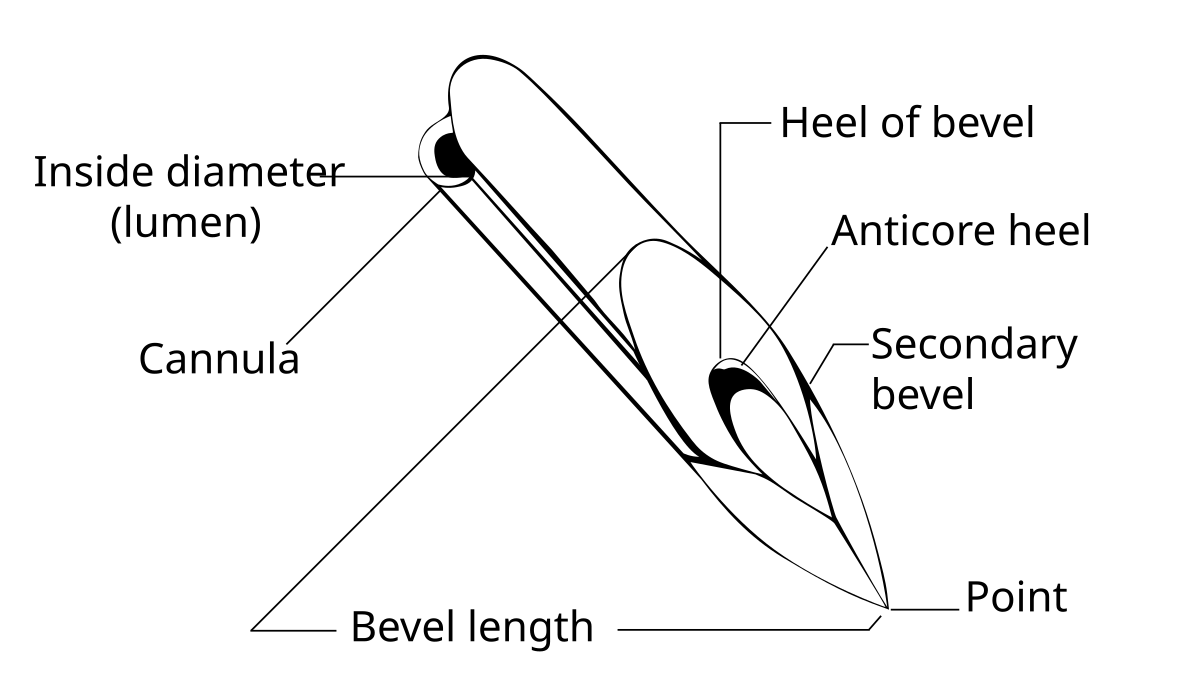

Definition of hypodermic syringe. A hypodermic needle is used for rapid delivery of liquids or when the injected substance cannot be ingested either because it would not be absorbed as with insulin or because it would harm the liver.

A small syringe used with a hollow needle for injection of material into or beneath the skin synonyms example sentences learn more about hypodermic syringe synonyms for hypodermic syringe.

What is a hypodermic syringe. Ligature needlea long handled slender steel needle having an eye in its curved end used for passing a ligature underneath an artery. 2003 by saunders an imprint of elsevier inc. There are many possible routes for an injection with intramuscular into a muscle and intravenous into a vein being the most common.

Knife needlea slender knife with a needle like point used in ophthalmic operations. As a verb syringe is to clean or inject fluid by means of a syringe. They may also be used to take liquid samples from the body for example taking blood from a vein in venipuncture.

Miller keane encyclopedia and dictionary of medicine nursing and allied health seventh edition. A hypodermic hypo under dermic the skin needle is a hollow needle commonly used with a syringe to inject substances into the body or extract fluids from it. Hypodermic syringe one for introduction of liquids through a hollow needle into subcutaneous tissues.

Med a type of syringe consisting of a hollow cylinder usually of glass or plastic a tightly fitting piston and a hollow needle hypodermic needle used for withdrawing blood samples injecting medicine etc. As nouns the difference between syringe and hypodermic is that syringe is a device used for injecting or draw drawing fluids through a membrane while hypodermic is a hypodermic syringe needle or injection. Hypodermic needlea hollow sharp pointed needle to be attached to a hypodermic syringe for injection of solutions.

A hypodermic syringe is a type of tube that can be fitted to a hollow hypodermic needle to perform injections into or extractions from the body.

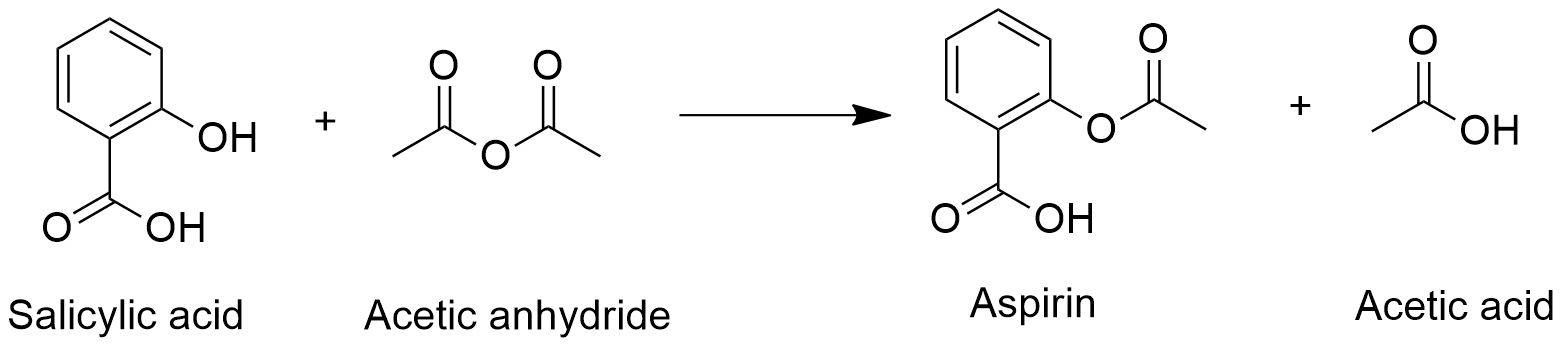

Its molecular formula is c9h8o4. Extended molecular formula of aspirin.

Structural Chemical Formula Of Acetylsalicylic Acid Aspirin Royalty Free Cliparts Vectors And Stock Illustration Image 27535459

Structural Chemical Formula Of Acetylsalicylic Acid Aspirin Royalty Free Cliparts Vectors And Stock Illustration Image 27535459

Its systematic name is 2 acetyloxy benzoic acid.

Molecular formula of aspirin. Aspirin is a medicine that is used worldwide as an anti inflammatory or antipyretic agent. It is formed by an aromatic ring having two functional groups where the first group is carboxyl group and the second group. Average mass 180 157 da.

The chemical formula for the compound is c9h8o4 and its molecular weight is 180 159 g mol 1. The chemical formula of aspirin is c 9 h 8 o 4 and the atoms are arranged according to the following diagram. Aspirin is a white crystalline powder with a melting point of 135 c.

Chemical formula of aspirin acetylsalicylic acid c 9 h 8 o 4. The molecular formula of acetylsalicylic acid aspirin one of the most commonly used pain relievers is c 9 h 8 o 4. Aspirin hc9h7o4 or c9h8o4 cid 2244 structure chemical names physical and chemical properties classification patents literature biological activities safety hazards toxicity information supplier lists and more.

Molecular formula c 9 h 8 o 4. It is not recommended during pregnancy and to children with infections. The common chemical name for aspirin is acetylsalicylic acid.

This is the reason aspirin is also known as acetylsalicylic acid. Monoisotopic mass 180 042252 da. Ch 3 cooc 6 h 4 cooh.

Aspirin decomposes rapidly in solutions of ammonium acetate or the acetates carbonates citrates or hydroxides of the alkali metals it is stable in dry air but gradually hydrolyses in contact with moisture to acetic and salicylic acids in solution with alkalis the hydrolysis proceeds rapidly and the clear solutions formed may consist entirely of acetate and salicylate. Aspirin is nsaid nonsteroidal anti inflammatory drug but it suppresses the normal functioning of platelets.

Flush toilets can be designed for sitting in which case they are also called western toilets or. The invention of the flush toilet historians date the first mention of a flush toilet back to 1596 when the godson of queen elizabeth i sir john harington described it in writing.

Facts About Flushing Toilet Invention Dk Find Out

Facts About Flushing Toilet Invention Dk Find Out

According to his description the toilet was an oblong bowl that was two feet deep and waterproofed with a mixture of pitch resin and wax.

When were flushing toilets invented. A flush toilet also known as a flushing toilet water closet wc see also toilet names is a toilet that disposes of human waste urine and feces by using water to flush it through a drainpipe to another location for disposal thus maintaining a separation between humans and their waste. Harington s device called for a 2 foot deep oval bowl. It is a widely held belief that thomas crapper designed the first flush toilet in the 1860s.

The first modern flushable toilet was described in 1596 by sir john harington an english courtier and the godson of queen elizabeth i. It was actually 300 years earlier during the 16th century that europe discovered modern sanitation.

Share your videos with friends family and the world. Kids today are just as fascinated by how things are made and they ve got a lot more videos to choose from.

How Things Are Made From Automobiles To Zippers Terranova Andrew Ebook Amazon Com

How Things Are Made From Automobiles To Zippers Terranova Andrew Ebook Amazon Com

Watch and learn how things in this word are made.

How things are made. Traditional tortilla preparation involves cooking the corn in pots over a fire steeping soaking for 8 to 16 hours pouring off the cooking liquor or nejayote and washing the nixtamal the end product of the cooking steeping and washing draining process. The basic method of tortilla and tortilla chip production has changed little since ancient times. Don t forget to hit like share and subscribe for more free new videos and updates.

Watching these videos together is a terrific way to encourage the next generation of engineers designers construction workers and more. There was a temporary exhibition on in the south of spain which exhibited everyday items such as the paperclip an umbrella lego bricks resealable plastic bags pencils and. Share with your classmates which product or thing you researched please be sure to provide a link to the video or article too.

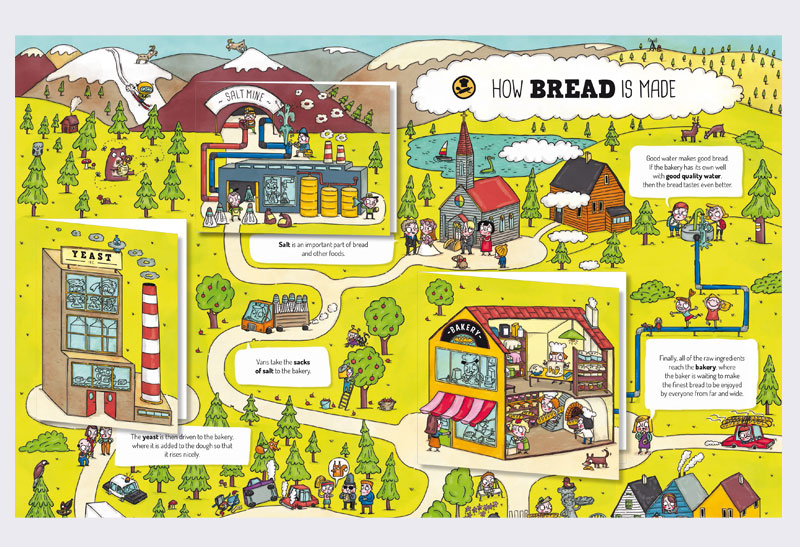

The site provides step by step descriptions of the assembly and the manufacturing process complemented with illustrations and diagrams each product also has related information such as the background how the item works who invented the product raw materials that were used product applications by products. Children have always wanted to know the answer to this question and this fun and eye catching book provides answers. Go to the youtube channel how things are made or some other site where you can see how things are actually made.

Breweries cheese making factories paper mills distilleries we are inquisitive and we pay lots of money to visit these factories and find out how things are made. Here are some of our favorites. With six large gatefolds and 26 booklets it s chock full of fun facts that take kids through the life cycle of everyday objects like t shirts books bread chairs and glassware.

Select a product or thing and watch the video and or read the information provided. How products are made explains and details the manufacturing process of a wide variety of products from daily household items to complicated electronic equipment and heavy machinery. How was this made.

Welcome to how things made.

Heyl filed patent number 195 603 for the first machines to both insert and clinch a staple in one step and for this reason some consider him the inventor of the modern stapler. Heyl filed patent number 195603 for the first machines to insert and clinch a staple in a single step.

Stapler Do You Know Stapler Is Invented In 18th Century

Stapler Do You Know Stapler Is Invented In 18th Century

However the first patented stapler was the paper fastener created by the novelty manufacturing company.

Invention of the stapler. The first stapler in recorded history was the stapling machine or fastener of king louis xv of france in the 1700s. The staples were allegedly made of gold covered with precious stones and included the royal court s symbol. Manufacturing co s inventions were to be used to staple boxes and books.

Of philadelphia pa 8 however the n. It was not until 1895 would the first stapler be known as the first modern stapler. The first stapler was made for king louis xv of france in the 18th century while the first patent to be awarded for a stapler was in 1866 by an american named george mcgill.

Modern paper fastening devices started with the patent of the first paper fastener on september 30 1841 by samuel slocum. For the first time in 1869 the stapler hit the market. The next year in 1867 he received a patent for a machine that would press his fastener through the paper.

This crude device stuck pins on paper to fasten them. In 1877 henry r. Legend has it that the first stapler was invented in the 1700s for king louis xv.

Each staple had to be handmade and was inscribed with the insignia of the royal court. In 1876 and 1877 heyl also filed patents for the novelty paper box manufacturing co. In 1877 henry r.

The inventor named george mcgill received a patent for a bendable paper fastener.

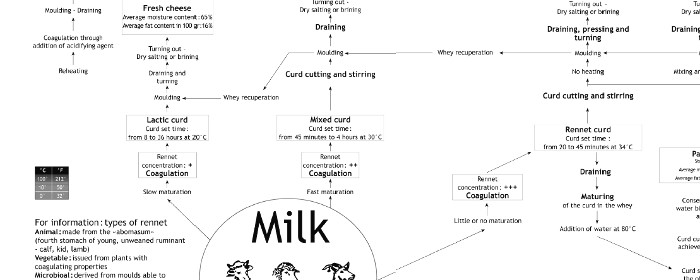

Due to the different production process the nutrition profile is very different from other types of cheese. Some types of fresh cheese have a smooth and creamy texture that makes it easy to spread on crackers bagels or toast.

How Are Different Cheeses Made Revealed Sprout Monk

How Are Different Cheeses Made Revealed Sprout Monk

There are many ways in which traditional cheeses can be described or classified.

What makes different cheeses. Criteria such as country of origin type of milk used species of animal used to produce the milk fat content moisture content texture whether mould ripened or not cheese making process used moisture in the non fat solids have been and continue to be used. Triple cream cheeses are enriched to at least 75. Crostini with mozzarella cheese.

This is a list of cheeses by place of origin cheese is a milk based food that is produced in wide ranging flavors textures and forms hundreds of types of cheese from various countries are produced. This cheese making process results in a white cheese with a mild taste. Their styles textures and flavors depend on the origin of the milk including the animal s diet whether they have been pasteurized the butterfat content the bacteria and mold the processing.

Making cheese is an ancient practice dating back thousands of years and the home makers can usually find recipes that fall into any of the four categories. Double cream cheeses are soft cheeses of cows milk enriched with cream so that their fat in dry matter fdm or fidm content is 60 75. Like other cheeses fresh cheeses can be made from different types of milk and varying amounts of salt which gives them distinct flavors.

Cottage cheese is very different from most other varieties and its closest relation is probably ricotta. There are different cheesemaking techniques which have developed over time in response to new technologies and changing consumer demand. Sometimes cheeses marketed under the same name are made from milk of different animal feta cheeses for example are made from sheep s milk in greece.

Since types of cheeses are listed by firmness moisture levels play an important role in the selection process. The texture of fresh cheese also depends on how much whey and moisture is drained from the final product resulting in everything from soupy cottage cheese to crumbly queso fresco. Soft types includes cottage cheese cream cheese ricotta brie bleu roquefort mozzarella muenster and similar varieties.

The difference with fresh cheese is that they are not aged or ripened as other varieties of cheese are. This famous cheese is made by acidifying curds from milk with a bacterial starter culture. Cheese comes in many different styles textures and flavours.

Different cheeses have developed in different regions influenced by their unique culture and environment. Higher moisture content results in a softer cheese while lower moisture content that is densely packed into cheese molds results in a harder cheese.

Generally an eraser comes under the essential school. Basically an eraser helps to remove pencil and sometimes pen writings.

How To Make Pencil Eraser Sharpener Dispenser Machine Youtube

How To Make Pencil Eraser Sharpener Dispenser Machine Youtube

To make flat rectangular erasers the mixture is injected into molds and then cooled.

How to make pencil eraser. Next use sand paper to smooth rough edges and remove about half a millimeter of material off the top and bottom. Then slide the eraser off the pencil carefully to keep its shape before putting in the oven or hot water to set. Erasers have a rubbery consistency and are often white or pink although modern materials allow them to be made in any color.

You can even make your own silicone mold of any object using mold putty. This is my favorite type of eraser and i use it in almost all of my tutori. How to make an eraser drawing.

Use your pencil to shade in the paper until the entire paper is shaded grey. If you want to make an eraser that fits on the top of a pencil use the end of a pencil to make an indentation in your eraser clay design or shape the clay right onto the pencil. To make a pencil topper eraser just take a pencil and push it in to the clay and mold it around the pencil top till you get the shape you want.

In order to make eraser plugs that will be attached to the ends of pencils the rubber mixture is extruded and cut into plugs. Use the eraser on your pencil to draw something. 10 the mixture is heated causing the sulfur to vulcanize it making it more stable.

Learn how to easily turn any solid eraser into a kneaded eraser tips and tricks. Make sure the top of the stick is flat and straight. In addition to that typewriters tailors bookkeepers use the eraser on regular basis.

Click here for free printable copy email subscribers only. Kersey campbell for erasers with different parts try blending the backside of the eraser together to help keep the pieces intact. Try a silicone mold if you want to make your erasers into clearly defined shapes.

Hold the stick down very firmly and make light passes with the blade.

Potato flake is. Different varieties of potatoes are usually used for chips.

How Potato Chip Is Made Used Processing Product Machine Raw Materials

The production process mainly comprises of the following steps washing and peeling fully grown and ripe potatoes are firstly thoroughly washed before peeling them with the help of a peeler.

Potato wafers manufacturing process. Then trim them and place in water to prevent browning. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the. You can peel the potatoes manually with a stainless steel knife or using an abrasive potato peeling machine.

If 20 potato wastage occurs due to small size and blacking. A wafer making machine with a 0 33 hp motor. You can produce the 150 kg per 8 hour shift to 1 ton per 8 hour shift.

Potato is widely consumed as food all over the world. Basic raw material required. Potato chips manufacturing business can be initiated on a small scale with moderate capital investment.

Potato chips are basically used for snacks purposes. All process of making potato wafer chips is done by machine. First of all wash the potatoes thoroughly and peel them.

There is no need to dry potato slice in day light. Balaji wafers pvt. It is depends on your plant.

Project report on potato wafers chips project report on potato wafers chips includes present market position and expected future demand technology manufacturing process investment opportunity plant economics and project financials. Potato chips manufacturing process with flow chart. Potato is basically used as a snack item.

Then wash the peeled potatoes with sprays of water. Potato wafer is very beneficial business for low budget plant. They are produced by rapid dehydration of potato slices by direct contact with hot oil.

The production of potato flakes has huge potentials in the fast growing indian market. Potato wafers must be manufactured in a scientific manner and under hygienic conditions. They are produced by rapid dehydration of potato slices by direct contact with hot oil.

Potato is widely consumed as food all over the world. Its crispiness and special palatability makes it the favourite of people of all age groups. Ravi and suggest whether she should.

Garlico industries ltd. Chips manufacturing unit for mrs.

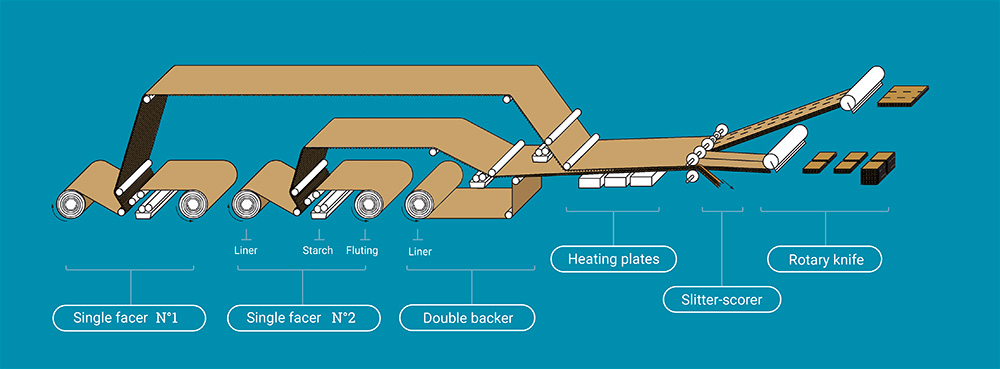

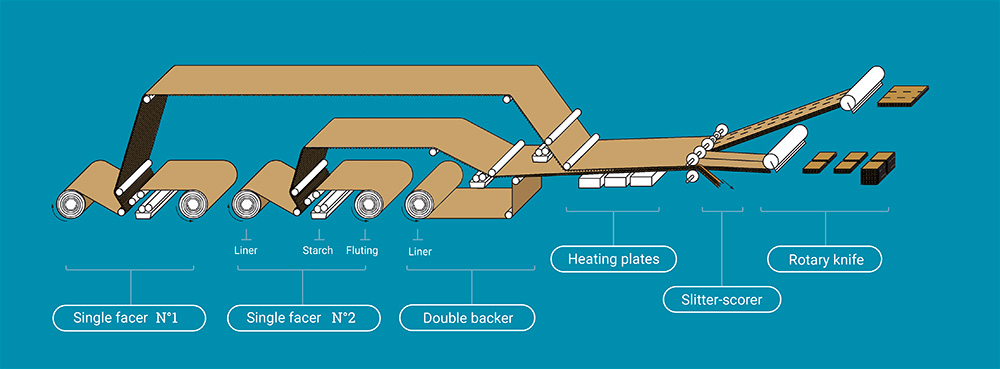

To understand this process with a simple illustration you can take a piece of paper and add waves in it known as flutes. Steam is vital to the corrugated box making process.

The Production Of Modern Corrugated Packaging Fefco

The Production Of Modern Corrugated Packaging Fefco

Corrugated cardboard manufacture includes two key steps.

Corrugated cardboard manufacturing process. Electricity water 1 paper mill customers conversion process. A process of manufacturing of corrugated cardboard type packaging container in which a corrugated core liner adhered at its one side surface to one side liner is applied at its other side surface with an adhesive agent and then with a reinforcing agent and thereafter is adhered to the other side liner to form reinforced corrugated cardboard and before completion of hardening of the. The auxiliary facilities that are used at a corrugated packaging plant.

The corrugated paper manufacturing process. Cardboard as you are likely to be aware of is manufactured using fibres from trees plants. From making the adhesive that conditions the layers of paper to heating the pressure vessels that bond the fluted medium to the liners steam generation is an invaluable process.

Corrugated cardboard boxes manufacturing unit with printing manufacturing plant detailed project report profile business plan industry trends. The process for making corrugated boxes involves six steps that begin with sustainable timber harvesting and finish up in a specialty carton plant like the one used by fg s. Pulp is not only produced from timber but can also be created in an environmentally friendly way by recycling woodchips and shavings leftover from lumber mill waste.

Kraft paper involves pulping wood chips and then feeding the resulting paper substance through massive steam rollers that remove the water. Manufacturing process 16 1 corrugated board manufacturing process 16 2 corrugated board box manufacturing process 17. Before being recycled this waste used to be disposed of at landfills or was burnt.

Making kraft paper and corrugating the cardboard. Figure 1 overview of manufacturing process flow for corrugated packaging the discharge of all class i designated chemical substances at the points indicated by the dotted boxes graphic are subject to reporting. Corrugating is also done in a machine that utilizes heavy rollers.

The corrugated board production process is to first print the facial tissue and then combine it with corrugated medium paper and cardboard. The invention relates to a process for manufacturing corrugated board in which the corrugated board is produced by gluing at least three individual constituent webs 3 5 7 respectively on two sides oriented toward each other wherein in a single work cycle at a first glue application point a a first constituent web 3 is coated with glue and at a second assembly point b the first constituent web 3 is glued to a second constituent web 5 to form a half finished web 31 and. The printing process is an flexo with water base liquid with nylo rubber stereo.

Even though the condensed steam is reprocessed the cost of boiler fuel is a large factor in packaging manufacturing. The 1st one is while making 3 ply 5 ply board sheet the top paper is printed separately pasted. Semi automatic corrugated board production line production process.

The corrugated cardboard produced by the process is conventionally formed into a box by using die cutting indentation and sticking. There are various methods of this process. The 2nd process is directly to print on 3 ply 5 ply board sheet.

The most common types of shoes worn with a taller heel are pumps stilettos and heeled sandals. Wedge heels and wedge sandals.

Find The Right Shoes For Your Leg Shape Potentash

Find The Right Shoes For Your Leg Shape Potentash

It s described by a long thin heel often found on boots pumps.

Different types of heel shoes. Instead this design features a seamless line that runs from the ball of the foot to its heel in a wedge shape. Different kinds of heels 11. If you are a heel aficionado read on to see if there s more to heels than you thought there was.

Maxi gowns and jeans. The french heel commonly known as pompadour heel or louis heel are similar to spool heels only difference is spools are a little curvaceous vertically while french ones are flatter or simpler. Kitten heel kitten heels are great if you re uncomfortable walking in higher heels or if you re on the taller side but don t want to abstain from wearing pretty heels because of it.

High heels come in all kinds of shapes and heights. Wedge heels there are two different types of wedge shoes. Wedge heels are flush just like a high heel would be and there is no separation from the heel to the sole.

But wait do you know about all the different types of heels there are and how to style them. There are two different types of wedge shoes. The stiletto heel one of the most classic and popular heel styles is named after the stiletto dagger dating back to the 1930s.

Every heel of at least four inches or more can fall into this category. Wedges are just like high heels but there is no separation from the heel to the sole. If you are new to the heel game and are not sure you have come to the right place.

Different types of heeled shoes 10. Very high heels can reach heights of up to eight inches or more. And it goes without saying that heels are our favorite kind of shoes.

Wedge sandals while they have the same type of heel as a wedge heel wedge sandals have a more open sandal upper. The most common types of shoes worn with a taller heel are pumps stilettos and heeled sandals. Wedge heels and wedge sandals.

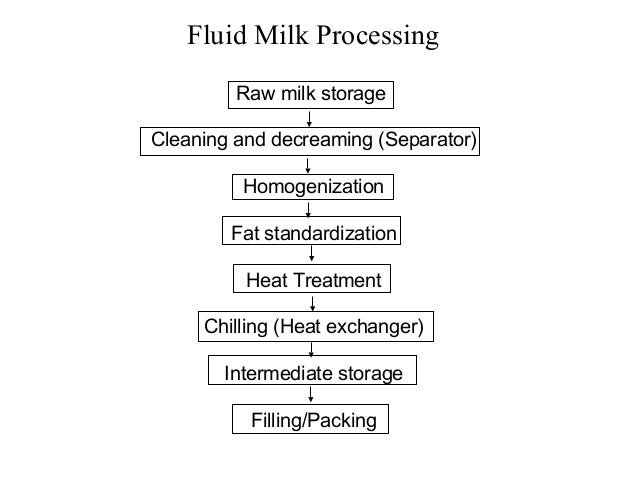

Heat the milk to between 72 c to 74 c for 15 to 20 seconds. Ultra high temperature uht pasteurization.

The spinning causes the milk to separate from debris and floating bits of bacteria.

Stages of milk processing. Pasteurization is a heat treatment process that. Most of the milk in developing countries is processed by small scale processors who produce a variety of milk products. The usable life of milk can be extended for several days through techniques such as cooling which is the factor most likely to influence the quality of raw milk or fermentation.

The milk produced during buffaloes lactation period differs due to region and availability of feed. Whole milk once approved for use is pumped into storage silos where it undergoes pasteurization homogenization separation and further processing. The extreme heat targets coxiella burnetii which causes q fever.

Milk processing allows the preservation of milk for days weeks or months and helps to reduce food borne illness. The type of processing employed may vary from country to country and region to region depending on local tastes dietary habits culinary traditions and market demand. Milk is picked up by a handler who takes a sample and then pumps the milk from farm s bulk tank into the milk truck.

Milk is obtained from the cow or goat sheep or water buffalo under sanitary conditions and cooled to 45 f 7 c within 2 hours of milking. However its thermal stability is lower so mixed milk a mixture of buffalo and cow milk is preferable for ultra high temperature uht treatment. After clarification is completed the milk is spun once again to separate heavier and lighter milks.

Clarification is a step in milk processing that ensures the milk will be free of bacteria and debris. Milk is put into large vats that continually spin. Lactation secretion and yield.

Targets resistant pathogenic bacteria spores clostridium botulinum spores. The milk is sent through stainless steel pipes to large refrigerated vats then stored at 5 c or less. Heat the milk to between 135 c to 140 c for 2 to 4 seconds.

Within 48 hours milk is taken in tankers to a milk factory where it s pasteurised and homogenised. Milk from buffaloes can be processed like milk from cows. Every particle of milk is heated to a specific temperature for a specified period of time and cooling it again without allowing recontamination.

White feather country store is the durham region s largest country store. Monday 12 21 20 open 9 00 to 5 00 tuesday 12 22 20 open 9 00 to 5 00.

White Feather Farms Chicken Truck Www Oronofair Com Orono Chicken Farm Parades

White Feather Farms Chicken Truck Www Oronofair Com Orono Chicken Farm Parades

Open 7 days a week.

White feather farms hours. White feather country store oshawa. We sell our own farm fresh chickens and eggs. We also carry local.

A beautiful natural haven for dogs the white feather farm is a luxurious natural retreat with a state of the art private spa and indoor pool with the property boasting hi. Branding and website by the artful union. White feather has everything from fresh apple fritters to home decor.

321 bucktoe rd avondale pa 19311. White feather farm is a canine naturopathic spa and retreat situated on the 12 acre homestead of diane mayer rob mayer. Our goal is to also showcase local heirloom plants and provide food security for members of our community in need.

We focus on soil regeneration cultivating biodiversity and sequestering atmospheric carbon. Opened its doors 1988. Home about offerings connect peaches teaches terms policies.

White feather country store. Oshawa ontario l1h 0m9. See 342 reviews articles and 16 photos of white feather country store ranked no 1 on tripadvisor among 5 attractions in oshawa.

15 raglan road e. We will have special holiday hours for christmas and new year s eve. 6 515 likes 17 talking about this 5 003 were here.

The white feather farm lands are intentionally and reverently tended. White feather farms oshawa phone number website address opening hours on frozen food stores. White feather farms inc.

Thus the term fresh if it is used with implications of quality rather than as a description of the consistency of recently made raw pasta has no significance whatever. Many people who make pasta regularly use a pasta rack with many wood dowels to drape the pasta over to dry.

Making Homemade Noodles Safely Answerline Iowa State University Extension And Outreach

Making Homemade Noodles Safely Answerline Iowa State University Extension And Outreach

Others use laundry racks.

How to dry pasta for storage. While filled pasta should be consumed as soon as possible it can be frozen for up to a month for later use. The thin noodles will dry quickly so you want them in the right shape for that. If you are drying pasta bianca a dough made of simply flour and water leave your pasta uncovered in a dry area for 12 to 24 hours carefully turning it at regular intervals.

A fan can be a big help ensuring your homemade pasta dries quickly and evenly. Dry pasta will take longer to cook than the fresh but when cooked there is no difference between them in taste or consistency. Since pasta has very little moisture content it s not very susceptible to spoiling compared to other foods.

Most people keep it in their pantry or kitchen cabinet. Drying homemade pasta takes just a little advance planning and can provide a simple way to store large batches for later use. Don t use too much flour especially if it is hot outside or inside your home.

Leave the pasta uncovered in a dry area for 12 to 24 hours gently stirring and turning it a few times. Even if you leave your pasta in an open bag or box it s not in much danger if you ll be using it relatively soon. The recommended storage for dry pasta is in a cool dry place.

It s easy try it yourself. Pasta has to be quickly laid out or hung to dry as soon as it comes through the machine or as it s rolled and cut. The humidity might cause issues.

Animal insulin is derived from cows and pigs. Insulin degludec tresiba is a once daily long acting insulin providing a basal dose of insulin lasting beyond 42 hours.

Within 24 hours leonard s dangerously high blood glucose levels dropped to near normal levels.

Insulin first used to treat diabetes. A second dose purified by james b. These days the use of animal insulin has largely been replaced by human insulin and human analogue insulin. Leonard lives another 13 years before succumbing to pneumonia.

In january 1922 14 year old leonard thompson was the first person to receive an injection of insulin to treat diabetes. It the only basal insulin approved for both type 1 and type 2 diabetes. Animal insulin was the first type of insulin to be administered to humans to control diabetes.

A 14 year old boy with type 1 diabetes called leonard thompson is given the first medical administration of insulin. Taking insulin helps you manage your blood sugar levels. Many types can be used to treat diabetes.

When your body isn t making or using insulin correctly you can take man made insulin to help control your blood sugar. They re usually described by how. Pumps aren t available to everyone only for people who have type 1 diabetes.

Insulin was discovered by sir frederick g banting pictured charles h best and jjr macleod at the university of toronto in 1921 and it was subsequently purified by james b collip. Everybody with type 1 and some people with type 2 diabetes need to inject i nsulin to help manage their blood sugar levels. First the absorption of regular human insulin from the subcutaneous tissue is slow and the metabolic action takes effect only 30 60 min after injection and peaks after 2 3 h.

Leonard lives for another 13 years. Until the 1980s animal insulin was the only treatment for insulin dependent diabetes. The news about insulin spread around the world like wildfire.

On 11 january 1922 insulin was first used in the treatment of diabetes. Previously patients with type 1 diabetes would be put onto starvation diets and would have only months to live. Pramlintide was the first in a class of injectable anti hyperglycemic medications for use in addition to insulin for type 1 diabetes or type 2 diabetes.

In january 1922 leonard thompson a 14 year old boy dying from diabetes in a toronto hospital became the first person to receive an injection of insulin. You take insulin by injecting it using an insulin pen or by using an insulin pump. Consequently treatment with regular insulin is associated with postmeal hyperglycemia and an increased risk of late postprandial hypoglycemia.

Thompson lived another 13 years with the condition and eventually died of. Pramlintide is a synthetic analog of human amylin a naturally occurring hormone made by the pancreas to help control glucose after meals.

Many claims have been made for. The number of electrons in each of sodium s shells is 2 8 1 and its electron configuration is ne 3s 1.

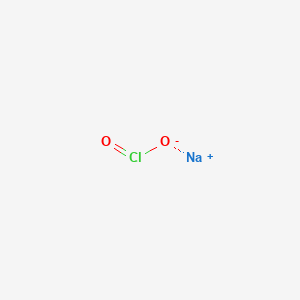

Sodium chlorite 4 burke s.

Formula for sodium chlorite. Molecular weight 90 44. Sodium chlorite also referred to as chlorous acid sodium salt textone and miracle mineral solution is composed of sodium na chlorine cl and oxygen o 2. Sodium chlorite can be used to disinfect water.

Sodium chlorite naclo2 or clnao2 cid 23668197 structure chemical names physical and chemical properties classification patents literature biological activities safety hazards toxicity information supplier lists and more. Handbook of reagents for organic synthesis oxidizing and reducing agentshandbook of reagents for organic synthesis oxidizing and reducing agents. It forms the unstable chlorous acid when reacted with a strong acid.

Sodium chlorite technical grade 80 cas number 7758 19 2. Linear formula naclo 2. It is a powerful oxidizing agent it disproportionates sometimes.

11 is a block d group 5 period 4 element with an atomic weight of 22 989769. The sodium atom has a radius of 185 8 pm and a van der waals radius of 227 pm. Sodium chlorite is a colorless solid.

It is made by reducing chlorine dioxide in a basic solution of hydrogen peroxide. Pubchem substance id 329752483. See more sodium products.

Sodium chlorite is derived indirectly from sodium chlorate naclo 3. First sodium chlorate is reduced to chlorine dioxide typically in a strong acid solution using reducing agents such as sodium sulfite sulfur dioxide or hydrochloric acid. Wo2011017578 page 71 8 3 mb 2 wikipedia.