How Do You Make Contact Lenses

They minimize your risk of infection or product buildup. Use the results of the over refraction to pull new trial contact lenses and repeat the process.

How The Chinese Make Their Eyes Look Bigger With Contact Lenses

Soft contacts including new highly oxygen permeable varieties called silicone hydrogel lenses can be made with either a lathe cutting process or an injection molding process.

How do you make contact lenses. Still eye makeup can present problems if the makeup gets on around or the worst under the lens. The science of lens material is always being updated by lens manufacturers and the specific material of any contact lens may differ depending on the maker. After you remove the lens put it in the palm of your hand and wet it with contact solution.

New to contact lenses. Sometimes you may run out of contact lens solution when you really need to remove clean or store your contacts. Individually packaged disposable soft contact lenses are economically manufactured with an injection molding process.

Perform an over refraction on eye each using loose trial lenses or a phoropter. If you have allergies or wear eye makeup you can avoid infections through one time use disposable contact lenses. How are contact lenses manufactured from season 1 episode 1 of how it s made.

Pinch the lens with your thumb and index finger and remove from your eye. Measure the visual acuity of each eye individually. The process ends when the refraction over the contact lenses is zero for each eye.

In this condition you can make contact solution at home to protect your lenses for some time but you will eventually need to get the original solution for prolonged periods. A cup with boiled water a little bit of salt something to put your contact s in can also be two little cup s. Check out the full playlist for beginners http bi.

The manufacturing process contact lenses may be produced by cutting a blank on a lathe or by a molding process. Gently rub it for about 30. You ve probably read a lot about how to do your makeup if you wear glasses but i know more women who wear contacts than glasses on a daily basis and a lot of them like me love makeup.

Allen shows how to take out contact lenses and what to do if they get stuck.

How Are Lenses Made

Gp lenses contain very little water and remain rigid on the eye. Plastic as well as glass lenses are produced by successive stages of fine grinding polishing and shaping.

How Prescription Eyeglasses Lenses Are Made Fit Youtube

How Prescription Eyeglasses Lenses Are Made Fit Youtube

Stock lenses and semi finished lenses made of plastic are created in a casting process.

How are lenses made. A simple lens sees well through its center but its vision around the edges tends to blur. How gas permeable contacts are made most rigid gas permeable lenses rgp or gp lenses are made of oxygen permeable plastic polymers containing silicone and fluorine. Then the semi finished lens is ready for use.

Lenses that require it are tinted and each lens is compared to the sample to ensure a perfect match. First the lens designer calculates the best curvatures necessary for superior optical quality. Glass and plastic type lenses with the exception of polycarbonate are made from a molding process.

Special ingredients such as for improving uv absorption are added to the liquid materials called monomers. After your lenses are polished and engraved they go through inspection and any lens deemed flawed will have to be redone. This mixture is poured into molds hardened and then processed to reduce residual stress.

They are then dipped in a number of baths until they are perfectly cleaned. Lenses are made of optical glass or plastic. While the same process is used to produce lenses for telescopes microscopes binoculars cameras and various projectors such lenses are usually larger and thicker and require greater precision and power.

They focus light rays by refracting or bending them so that they meet or converge at a common point. Then a computerized program attached to a digital file and lathe cuts the inside top surface of the mold.

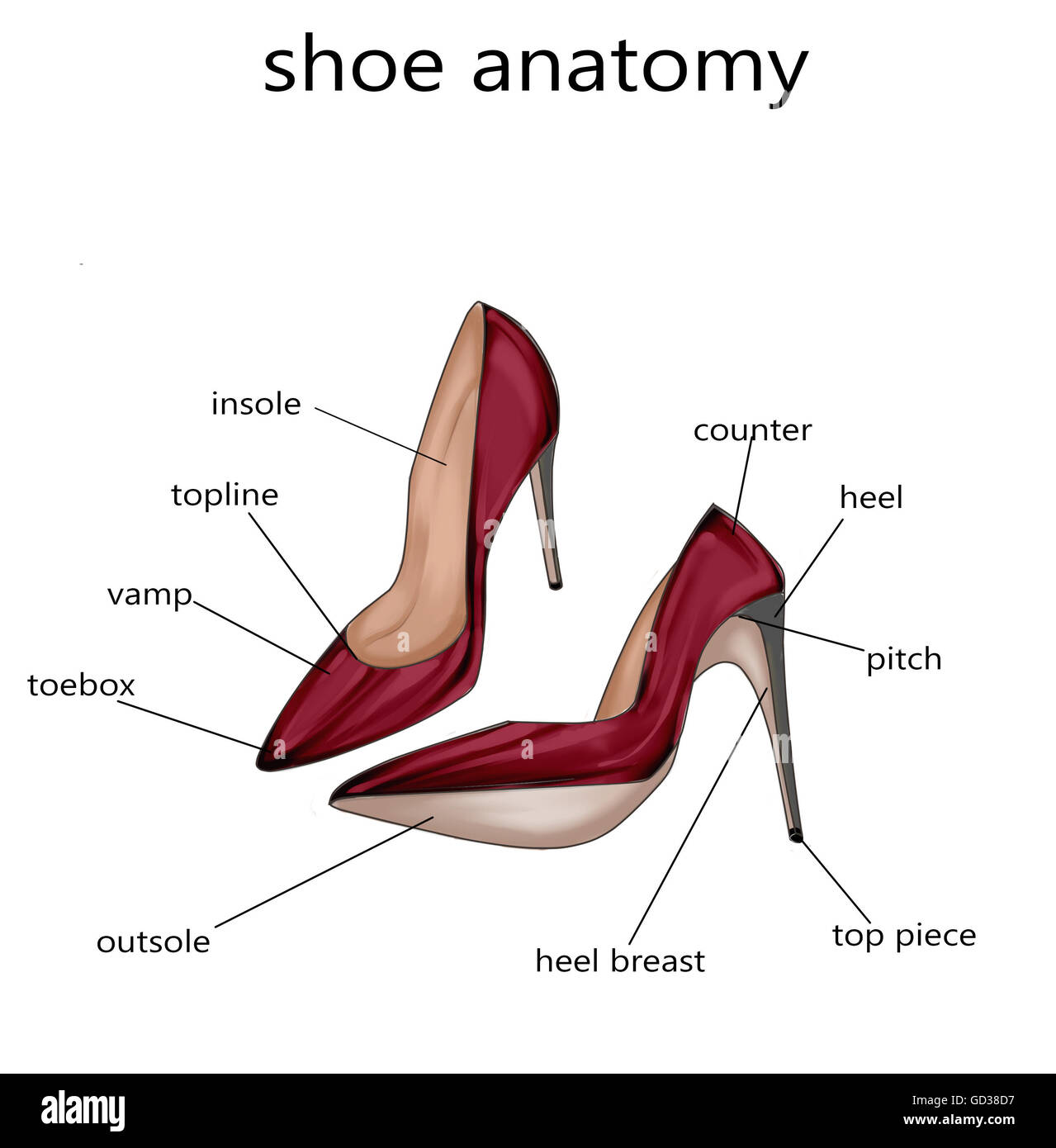

High Heel Shoe Parts

Lastly the heel is either screwed nailed or cemented to the shoe. The first step in high heel manufacture involves die cutting the shoe parts.

Anatomy Of A High Heel Part I Shoe Jargon Heels How To Make Shoes Shoe Lacing Techniques

Anatomy Of A High Heel Part I Shoe Jargon Heels How To Make Shoes Shoe Lacing Techniques

The heel is the part of the sole that raises the rear of the shoe in relation to the front.

High heel shoe parts. Next the components are drawn into a machine equipped with a number of lasts a shoe mold. Stiff panel behind the heel that adds shape and stability to back of shoe. The rear and sides of the upper that covers the heel which are behind the vamp.

Elastic or mesh panel that ensures a snug fit for slip on styles. See also heal seat and top piece. The top piece is the actual part of the heel that comes in to contact with the ground.

Rear portion of the shoe. The parts of the high heel are stitched or cemented together and then pressed. This is the top of the heel that touches the upper this is typically shaped to match the form of the upper.

High heel replacement tips 60pcs 30 pairs high heel shoe repair tips stiletto repair heel caps kit pin taps dowel lifts replacement 5 different size black 4 0 out of 5 stars 103 10 49 10. The part inside the shoe that makes contact with the sole of your foot. The heel section of the quarter is often strengthened with a stiffener which helps support the rear of the foot.

Also known as a footbed. Made of stacked leather or rubber pads the heel and adds height to back. The heel of a shoe is where the heel of your foot goes.

Often made of stacked leather heels are easily replaceable on good shoes. Shoe repair supplies consisting of things like leather replacement soles rubber soles stick on soles plastic soles vibram sole units heels replacement heels. The heel raises and supports the back of the foot and is typically made of stacked leather or rubber.

Leather stacked heel on a pair of red wing engineer boots. Metal or rigid leather perforations through which laces are fed. The part of the shoe that your foot s heel rests on.

The part of a shoe that cups the back of your heel.

How To Make Ice Skates

Hockey skates figure skates and speed skates. Adding the faux fur trim to your handmade felt ice skate ornaments.

I Learned To Ice Skate At Age 39 And I Cannot Recommend It Enough Self

I Learned To Ice Skate At Age 39 And I Cannot Recommend It Enough Self

The earliest skate artifacts were found in the bottom of a lake in switzerland and are estimated to.

How to make ice skates. The very first ice skates can be traced back to the ninth century and were made from animal bone. Well it s all fun. The player accelerates faster slides shorter distances and will no longer cause thin ice to break when landing from falls or jumps.

Push your feet apart while skating and stick one skate out sideways. Speed skates are designed for optimum swiftness in one direction with the skater moving right foot over left. Evenly distribute the weight from one foot to the other afterward to learn the one foot glide.

About press copyright contact us creators advertise developers terms privacy policy safety how youtube works test new features press copyright contact us creators. Ice skates are found in frozen chests in the ice biome. With both ice skates glued together and the ribbon in place we can move on to the fun part.

Stand together with your feet together. Once you re comfortable skating around the rink doing swizzles gliding and stroking you need to know how to stop. Ice skates are an accessory that improves a player s movement control on most forms of ice thin ice ice blocks the corrupted crimson hallow versions and ice rod blocks.

This stuff can get hella messy. Literally it s like you just shaved a cat. Each bar was made with a 90 degree on each end shorter pipes from the 90 degree pieces to the tees and then the longer piece in the middle.

First make the top bar and the front bar it required 4 x 2 3 4 side pieces and a centre piece of 7 1 4. To get a more customizable fit and to decrease break in time people bake their skates. With the 1 1 8 insertion length into the fittings that made the overall length 24.

I find it easiest to keep the mess under control if i cut a small. We show you how to do it in the comfort of your home baking temp. There are three basic types of ice skates.

The speed skate features a straight blade up to 18 inches 46 cm long and 0 03 0 06 inch 0 08 0 15 cm wide. They can also be found inside. Gliding is the most basic move in how to ice skate.

As ice skating has grown and developed as an activity and sport over thousands of years ice skates themselves have transformed and evolved in both structure and style. Start by marching into the rink slowly then carefully stand on both feet and try to glide using your body weight as required. This will push some frost off of the ice and cause your body to come to a stop.

If you ve stumbled across a pair of antique or vintage skates you may want to know how old they are before adding them to your personal collection.

How To Make Bowling Pins

Players may not cross this line when rolling their balls. Lumber is dried in large kilns for 8 10 days before being shipped to the plant.

Dharmajane Toddler Tuesday Bowling Diy Bowling Game Diy Bowling Diy Bowling Pins

Dharmajane Toddler Tuesday Bowling Diy Bowling Game Diy Bowling Diy Bowling Pins

About press copyright contact us creators advertise developers terms privacy policy safety how youtube works test new features press copyright contact us creators.

How to make bowling pins. How easy is that. A bowling pin is a complex assembly of several maple wood pieces. Help your child to stick some masking tape around the sharp inside rim of the tin cans.

Each made of still smaller pieces. All you have to do is paint each bowling pin white tie on a ribbon add the letters b o o and paint on a ghostly face. The pins are set up in a v formation.

Get more strikes leave less spares and win more bowling tournaments with brad and kyle free video http bit l. Apply a second coat to make sure they look crisp and white. Then let them paint the outside and bottom with white paint and leave to dry.

Let brad and kyle coach you in bowling. Like when you come across old bowling pins and you have the perfect idea for them. Using chalk or painter s tape place an xs on the ground where the pins will be placed.

This will help add onto the extra weight that will create more realistic falling bowling pins. When it reaches the plant entire planks are cut at once into. Sometimes working in an antique store has its advantages.

Using chalk or painter s tape mark a foul line. Using sand or water fill each one of the soda bottles equally about 1 4 of the way up. Each sub assembly is glued and clamped into a pressurized mold to build it into the next larger piece.

This is probably one of the easiest crafts ever.